|

|

05-06-2012, 08:11 AM

05-06-2012, 08:11 AM

|

#1

|

|

Site Team

Join Date: Jan 2012

Posts: 5,407

|

I looked over my tires and wheels this morning and noticed one of my grease Zerks is missing. I haven't got close enough yet but it looks like it just fell out. I'll get down there and in-speck it later today to be sure why it's not there.

Has anyone else had problems with these? I guess we'll have to check them all over and make sure they're tight.

__________________

SOB "The RV Wiseguy"

|

|

|

05-06-2012, 08:14 AM

05-06-2012, 08:14 AM

|

#2

|

|

Senior Member

Join Date: Feb 2012

Posts: 429

|

I have not noticed that, but haven't really thought about it until you mentioned it. I will look today when we hook up. Thanks for the heads up.

__________________

Happy campers - Kerry and Jere. 2010 Dodge 3500HD DRW with 5K ultimate airlift airbags and 2012 Redwood 36RE.

|

|

|

05-06-2012, 10:31 AM

05-06-2012, 10:31 AM

|

#3

|

|

Senior Member

Join Date: Mar 2012

Posts: 1,136

|

While there, it might be a good time to grease those fittings. Just from a quick visual, it looked to me that they were installed dry and never greased. I have to get under & do a closer inspection.

__________________

Mike & Pam '12 36RL, Kodiak Discs, 17.5" G114s H-Rated, SRE4000 w/HD Shackles, Joy Rider Shocks, Flex Air, 5.5 Onan, W&D, DW, 4 Scare Lights, (2) 6V Trojan T-145s; Progressive EMS-HW50C, Winegard DTV Sat, Sony/Denon 4K Home Theater, WiFiRanger EliteAC Pack, weBoost 4G-X Cell Booster.

2022 RAM 3500 Limited CC, LB, 4x4, DRW, Max Tow, Cummins HO, AISIN, 4.10, Mopar 30K w/OEM Prep, Transfer Flow 70gal Aux Tank/Toolbox.

|

|

|

05-06-2012, 10:59 AM

05-06-2012, 10:59 AM

|

#4

|

|

Site Team

Join Date: Jan 2012

Posts: 5,407

|

Mine had grease in them but obviously weren't tight

__________________

SOB "The RV Wiseguy"

|

|

|

05-06-2012, 03:35 PM

05-06-2012, 03:35 PM

|

#5

|

|

Junior Member

Join Date: Mar 2012

Posts: 11

|

I actually greased mine and when I disconnected from gun the fittings pulled out on 4 of them! Put them back in see what happens next service. Soon!!

__________________

Mac and Jodi

|

|

|

05-06-2012, 04:57 PM

05-06-2012, 04:57 PM

|

#6

|

|

Member

Join Date: Feb 2012

Posts: 52

|

Quote:

|

Originally Posted by Shaka

I actually greased mine and when I disconnected from gun the fittings pulled out on 4 of them! Put them back in see what happens next service. Soon!!

|

Shaka,

I wonder if your Grease Gun Coupling is too tight?

Many people don't know you can loosen the coupling by putting a wrench on the back and using some Channellocks on the knurled part and turn counter clockwise. See picture below...

We own a Hardware Store and I tell every customer who buys a new gun how to loosen it because the three little "paws" (or whatever they are called) inside are too tight, especially on a new gun, and if they don't do it nine times out of ten they will pull the zerk out when they try to disconnect.

Actually I keep mine finger tight and only tighten it on the zerk if it leaks grease when pumping, then I always loosen it back up before disconnecting.

HTH, Keith

|

|

|

05-06-2012, 08:11 PM

05-06-2012, 08:11 PM

|

#7

|

|

Senior Member

Join Date: Feb 2012

Posts: 361

|

WOW!!  I never knew that! Great info. there.

__________________

Chuck & Carol

Full Timers in our 2013 36FL with MoRryde 8000# IS suspension. Pulled by 2012 Sport Chassis with Hensley Trailer Saver Hitch.

|

|

|

05-06-2012, 08:16 PM

05-06-2012, 08:16 PM

|

#8

|

|

Senior Member

Join Date: Mar 2012

Posts: 243

|

Quote:

|

Originally Posted by UNDRPSI

WOW!!  I never knew that! Great info. there. |

Ditto!

|

|

|

05-06-2012, 09:02 PM

05-06-2012, 09:02 PM

|

#9

|

|

Senior Member

Join Date: Sep 2011

Posts: 467

|

Quote:

|

Originally Posted by KWire

Quote:

|

Originally Posted by Shaka

I actually greased mine and when I disconnected from gun the fittings pulled out on 4 of them! Put them back in see what happens next service. Soon!!

|

Shaka,

I wonder if your Grease Gun Coupling is too tight?

Many people don't know you can loosen the coupling by putting a wrench on the back and using some Channellocks on the knurled part and turn counter clockwise. See picture below...

We own a Hardware Store and I tell every customer who buys a new gun how to loosen it because the three little "paws" (or whatever they are called) inside are too tight, especially on a new gun, and if they don't do it nine times out of ten they will pull the zerk out when they try to disconnect.

Actually I keep mine finger tight and only tighten it on the zerk if it leaks grease when pumping, then I always loosen it back up before disconnecting.

How can it pull the zert out, when it is threaded in. I call BS.

Lillyputz

HTH, Keith

|

__________________

36RE Redwood LEMON

|

|

|

05-06-2012, 09:14 PM

05-06-2012, 09:14 PM

|

#10

|

|

Site Team

Join Date: Nov 2011

Posts: 1,342

|

Quote:

|

Originally Posted by KWire

Quote:

|

Originally Posted by Shaka

I actually greased mine and when I disconnected from gun the fittings pulled out on 4 of them! Put them back in see what happens next service. Soon!!

|

Shaka,

I wonder if your Grease Gun Coupling is too tight?

Many people don't know you can loosen the coupling by putting a wrench on the back and using some Channellocks on the knurled part and turn counter clockwise. See picture below...

We own a Hardware Store and I tell every customer who buys a new gun how to loosen it because the three little "paws" (or whatever they are called) inside are too tight, especially on a new gun, and if they don't do it nine times out of ten they will pull the zerk out when they try to disconnect.

Actually I keep mine finger tight and only tighten it on the zerk if it leaks grease when pumping, then I always loosen it back up before disconnecting.

HTH, Keith

|

I have greased a lot of agricultural equipment over the years and I have to admit that I did not know this bit of information. Thanks for pointing this out.

An additional bit of infomation about grease zerks. On our 36RL, I did not notice until we had our coach at home that one of the zerks was broken off on the Trailair Tri-Glide pin box. There are 3 zerks on each side of the pin box and one was broken. So, I purchase an extractor tool and some zerks from our local Tractor Supply store thinking that I could just remove the broken zerk and replace it. Well the reverse threads on the cheap chinese extraction tool stripped out and foiled my plans. So, when I dropped the trailer off at the dealer a week ago to have some other work done, I asked the service department to replace the zerk along with some other work that needed to be done.

Edited by: hoosierguy

__________________

Guy & Phyllis

2012 RW36RL,DualA/C,KodiakDiskBrakes,TrailAir Tri-Glide,GY_G614's,Roadmaster Comfort Ride Slipper Spring Suspension

2011Dodge3500Laramie,CrewCab,4x4,SRW,Michelins, LongBed,6.7LCTD,3.73,PullRiteSuper5th20.5KHitch, BlueOxBedsaver

|

|

|

05-06-2012, 09:22 PM

05-06-2012, 09:22 PM

|

#11

|

|

Senior Member

Join Date: Mar 2012

Posts: 619

|

KWire

Thanks for that bit of information never knew you could adjust the tips. What a great forum, i manage to pick up something almost every day

__________________

07 Dodge 3500, Exhaust Brake, Edge Programer, Killer "B" Turbo

13 RL ALL options except Gen and W/D

|

|

|

05-06-2012, 09:58 PM

05-06-2012, 09:58 PM

|

#12

|

|

Junior Member

Join Date: Mar 2012

Posts: 11

|

Thanks for that info.. Will give it a try!

__________________

Mac and Jodi

|

|

|

05-06-2012, 10:06 PM

05-06-2012, 10:06 PM

|

#13

|

|

Member

Join Date: Feb 2012

Posts: 52

|

Quote:

|

Originally Posted by lillyputz

How can it pull the zert out, when it is threaded in. I call BS.

Lillyputz

|

Lillyputz,

What are you calling BS?

That you can adjust the grease connector?

That you can pull out a grease zerk?

There are two types of grease zerks, thread in ones and drive in ones that have no threads, just rings that are supposed to hold them in by a tight fit. I don't know what type Shaka had that pulled out, but I know from experience I have had both threaded and drive in ones pulled out by too tight of a grease connector.

More and more what my customers have on their lawn mowers are just the drive in type and they do pull out easier than the threaded type.

Nevertheless, why would you want to run the risk?

Keith

|

|

|

05-07-2012, 06:07 AM

05-07-2012, 06:07 AM

|

#14

|

|

Senior Member

Join Date: Feb 2012

Posts: 959

|

Kieth you are absolutely correct! I also have had this problem with both types of zerks but if I pull a threaded zerk out it was usually loose to begin with.

__________________

"75 FEET OF FUN ON THE RUN"

|

|

|

05-07-2012, 11:31 AM

05-07-2012, 11:31 AM

|

#15

|

|

Senior Member

Join Date: Sep 2011

Posts: 467

|

Quote:

|

Originally Posted by KWire

Quote:

|

Originally Posted by lillyputz

How can it pull the zert out, when it is threaded in. I call BS.

Lillyputz

|

Lillyputz,

What are you calling BS?

That you can adjust the grease connector?

That you can pull out a grease zerk?

There are two types of grease zerks, thread in ones and drive in ones that have no threads, just rings that are supposed to hold them in by a tight fit. I don't know what type Shaka had that pulled out, but I know from experience I have had both threaded and drive in ones pulled out by too tight of a grease connector.

More and more what my customers have on their lawn mowers are just the drive in type and they do pull out easier than the threaded type.

Nevertheless, why would you want to run the risk?

Keith |

I stand corrected.

Lillyputz

__________________

36RE Redwood LEMON

|

|

|

05-09-2012, 11:30 PM

05-09-2012, 11:30 PM

|

#16

|

|

Site Team

Join Date: Jan 2012

Posts: 5,407

|

I called the factory and they called back yesterday saying that they are sending me a few Zerk. But today just for kicks and giggles I checked the others with just my fingers. 2 other grease Zerk were only finger tight. So I caution all of you to check these. They are a simple screw in type and easy to check.

__________________

SOB "The RV Wiseguy"

|

|

|

05-10-2012, 01:14 PM

05-10-2012, 01:14 PM

|

#17

|

|

Member

Join Date: Feb 2012

Posts: 52

|

Dave,

On our "Some Other Brand" (SOB) we have Dexter Eazy-Lube axles and they require a specific type or grade of grease. I have always been careful to make sure I use the same specification and not mix grease.

Does the manual tell you something similar for the Falcon axles?

Just wondering...

Keith

|

|

|

05-10-2012, 10:23 PM

05-10-2012, 10:23 PM

|

#18

|

|

Site Team

Join Date: Jan 2012

Posts: 5,407

|

Quote:

|

Originally Posted by KWire

Dave,

On our "Some Other Brand" (SOB) we have Dexter Eazy-Lube axles and they require a specific type or grade of grease. I have always been careful to make sure I use the same specification and not mix grease.

Does the manual tell you something similar for the Falcon axles?

Just wondering...

Keith

|

If you were repacking wheel bearings, I'd understand your concern about mixing grease. But these zerks are for friction points where 2 pieces of metal come together not high speed rotation. I wouldn't worry too much about it.

Just my opinion

__________________

SOB "The RV Wiseguy"

|

|

|

05-11-2012, 07:10 AM

05-11-2012, 07:10 AM

|

#19

|

|

Senior Member

Join Date: Feb 2012

Posts: 959

|

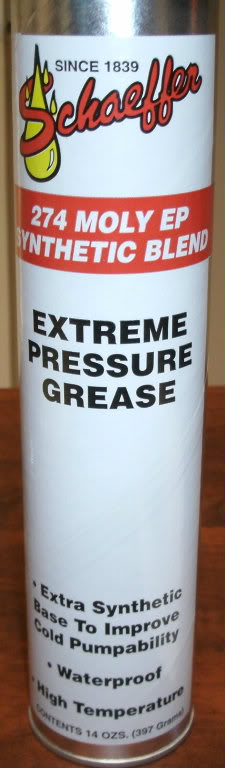

I use this grease made by Schaeffer it is waterproof and can be mixed with any grease.

__________________

"75 FEET OF FUN ON THE RUN"

|

|

|

05-11-2012, 05:34 PM

05-11-2012, 05:34 PM

|

#20

|

|

Member

Join Date: Feb 2012

Posts: 52

|

Thanks Bryan, I'll check it out. Keith

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|